The Power Meter,

Evolved

Power is more than a number.

Add meaning to your training with

SHIMANO's Force Vector analysis.

While power is important,

a simple output number doesn't give you the full picture.

Understanding how you develop power and finding ways

to improve efficiency can unlock new levels of performance.

SHIMANO's Force Vector feature gives you real-time feedback on your pedal stroke,

providing a more complete picture of your effort.

Visualize

Pedaling

Efficiency

Arrows indicate the direction

and amount of force you're applying to the pedals.

Blue arrows show force

rotating your cranks forward

while red arrows represent force

opposing transmission to the rear wheel.

Force Vector is made

possible

by SHIMANO's expertise

in designing

and manufacturing cranks

When designing power meters,

SHIMANO engineers consider crank structure,

the manufacturing process, materials used,

and how a crank flexes under load.

It's this expertise that allows SHIMANO

to achieve such accurate Force Vector measurement.

Using the latest technology

and SHIMANO's industry-leading knowledge,

the latest SHIMANO power meters

are powerful training tools.

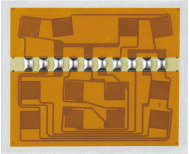

Optimal

sensor placement

SHIMANO power meters contain a total of 24 sensors (12 on each side) in a full bridge configuration*.

To accurately separate the force applied to the cranks in the tangential direction and normal direction, each sensor is positioned at an angle to compensate for crank deformation.

This uniquely-designed sensor increases the precision of measurement and enables Force Vector measurement.

*Full bridge configuration:

A sensor circuit configuration that improves temperature compensation with large sensor output.

Unified

left-right design

Although many power meters over the world

have a separate left-right configuration,

SHIMANO power meters have a unified left-right configuration.

A lithium-ion battery is incorporated inside the spindle

that connects the left and right cranks,

and provides power to the left and right sensors.

Wiring the left and right sensors together

eliminates minor deviations in measurement time

and enables accurate measurement of

power on both sides.

Long-life

battery

Power meters that have a lot of sensors and send a large amount of data have high power consumption. However, SHIMANO power meters achieve low power consumption thanks to a unique circuit configuration. A rechargeable lithium-ion battery enables long-term use while contributing to precision. The EW-EC300 Di2 charging connector is used for charging, making bicycle battery management easier.

| Continuous operation time |  |

|||

|---|---|---|---|---|

| Force Vector | Cycling power | OFF | ||

|

Force Vector | 70h | 230h | 230h |

| Bicycle power | 230h | 230h | 270h | |

| OFF | 230h | 270h | - | |

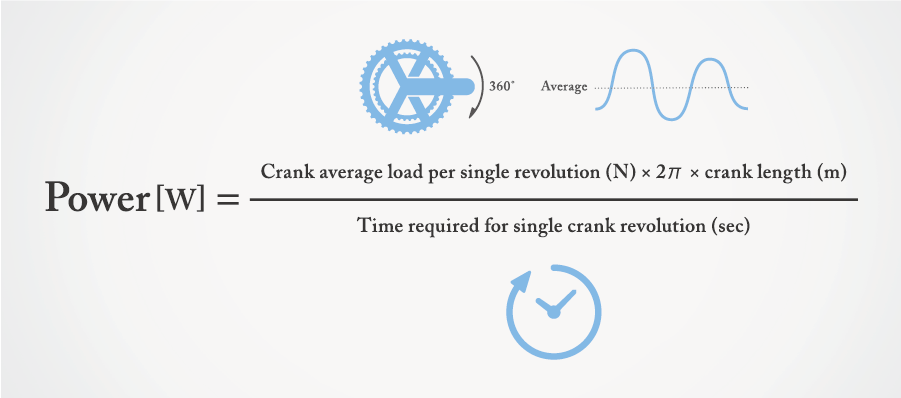

SHIMANO power meter characteristics

Power precision

Power cannot be measured directly. Therefore, it has to be calculated from measurements of load and time, using the formula below.

Power (W) = Crank average load per single revolution (N) x 2π x crank length (m) / time required for single crank revolution (sec)

Power measurement error is determined by the accumulation of load measurement error, time measurement error, and crank length variation. In order to reduce these errors and variation, SHIMANO power meters are structurally designed based on a careful examination of crank manufacturing methods. Additionally, thorough quality control measures are applied during manufacturing and calibration. For measuring load, each individual crank is calibrated in the factory before being shipped. Crank length is established in the processing stage, with minuscule variance. For the time measurement, measurement precision is improved with the use of magnets, and at a cadence of 90 rpm, the margin of error is a minuscule ± 0.15%.

SHIMANO power meter calibration

SHIMANO performs calibrations to accurately measure the power even if force is applied in a range of directions.

SHIMANO performs calibrations to accurately measure the power even if force is applied in a range of directions.SHIMANO load calibration conditions have been developed exclusively by SHIMANO based on a consideration of the conditions required for bicycle power meters, and with reference to JIS B 7728 and ISO 376 standards. Calibration is performed for a combined error of ± 1.5% or less with respect to the rated load.*

With regard to the rated load, loads of varying direction and size may be applied to multiple points on the pedals depending on conditions, but the standard value is established as 800 N. Calibration is performed based on a consideration of maximum loads, so that errors do not increase even under high-input loads as produced by pro riders. This means that stable power values can be calculated for general riders up to pro riders.

Combined error: At the maximum deviation from a straight line that connects the no-load point and the rated load point on the calibration curve, the combined error includes the following errors.

- Nonlinearity

- Reproducibility

- Repeatability

- Zero error

Calibration is performed in a managed environment at a temperature of 18 to 28°C and a humidity of 35 to 75%.

* For FC-R9100-P/FC-R8100-P, ± 2.0% or less.

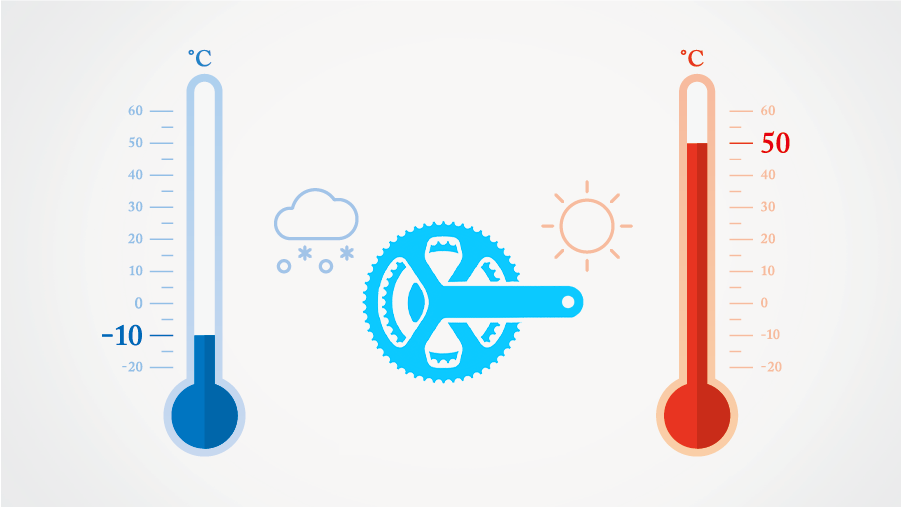

Temperature compensation

Operating temperature

Operating temperature-10°C to 50°C

Because of the properties of aluminum and strain gauges, the zero-point balance of the gauge changes as the temperature changes. This increases the load measurement error. To compensate for this, with SHIMANO power meters, each and every crank is subject to temperature calibration in the factory. When a 2°C change from the time of the zero offset occurs in the environment temperature, the zero point is automatically adjusted.