Drive rigidity

Drive rigidity

Rigidity decomposition and drive rigidity

It is already known that rigidity and driving force are inseparable. However, it was not known which of the following three elements relates to driving force: lateral rigidity, longitudinal rigidity, or drive rigidity. Accordingly, Shimano created multiple prototypes with different parameters and has spent about three years assessing them with a professional team.

It was the sample with improved drive rigidity that received positive feedback, such as “It travels smoothly” or “It runs fast,” from almost all riders. In other words, it was found that drive rigidity is most closely related to driving force.

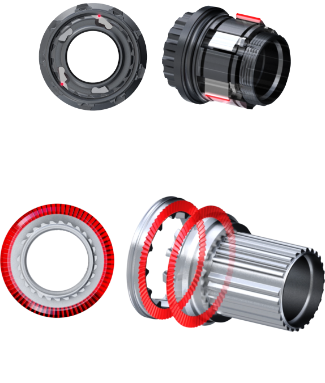

A direct engagement system was developed to increase drive rigidity. Compared to the conventional Pawl Ratchet structure, the contact area is increased, and ratchets are more firmly fitted to each other while being driven due to the spiral shape. These have led to a substantial improvement of drive rigidity.

Furthermore, we have succeeded in reducing the weight of the entire hub by making the freehub body and main components of the ratchet from aluminum.

We have succeeded in significantly improving drive rigidity by using a hub that incorporates a direct engagement system. As a result, on C36 and C50, we have concurrently achieved weight reduction of the entire wheel while decreasing spoke diameter and maintaining great rigidity.

Rough breakdown of drive rigidity

Drive rigidity

Energy reduction