ICE TECHNOLOGIES

Los componentes ICE TECHNOLOGIES de SHIMANO ofrecen un rendimiento de frenado más uniforme mediante la reducción de la acumulación de calor en el sistema. Esto ayuda a prevenir el calentamiento de los frenos, que puede ocurrir cuando un ciclista aplica los frenos con fuerza de forma repetida durante un corto periodo de tiempo, por ejemplo, durante un descenso prolongado y pronunciado.

Los discos y pastillas de freno con SHIMANO ICE TECHNOLOGY reducen la acumulación de calor y proporcionan una potencia de frenado constante y fiable. Los discos tienen un diseño de sándwich de 3 capas de acero inoxidable-aluminio-acero inoxidable que irradia calor para mejorar el rendimiento. Las pastillas de freno tienen una aleta radiante de aluminio que ayuda a disipar el calor por todo el sistema.

Juntos, los discos y las pastillas de freno ICE TECHNOLOGY proporcionan una conducción más silenciosa, a la vez que reducen el calentamiento de los frenos y prolongan la vida útil de las pastillas para una experiencia de conducción más fiable y segura.

Pastilla ICE TECHNOLOGY

Disponible en resina o compuesto metálico, la pastilla de aleta de radiación opcional con placa trasera de 2 capas (aleta de aluminio con acero inoxidable) mejora, incluso más, el rendimiento de radiación.

AluminioInoxidable

AluminioInoxidableRotor ICE TECHNOLOGY

Los rotores revestidos, así como las pastillas de freno, reducen la acumulación de calor del sistema de frenos. A su vez, se reduce la fatiga, se garantiza un alto rendimiento constante, incluso en descensos prolongados, se prolonga la vida útil de la pastilla y se reduce el ruido.

Rendimiento de radiación

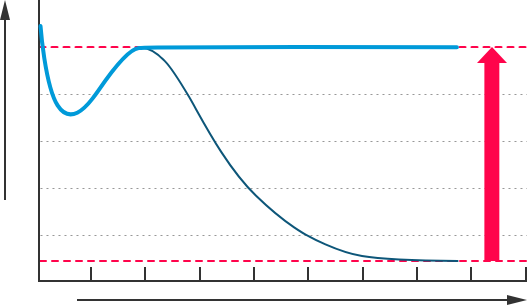

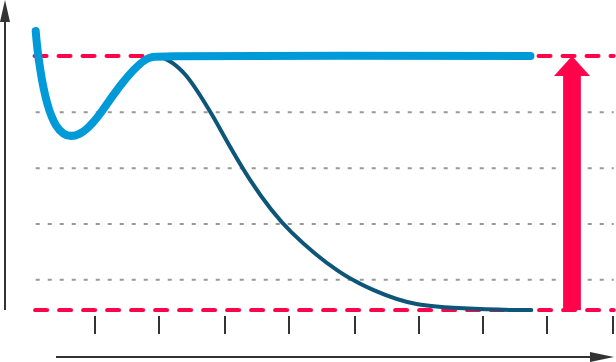

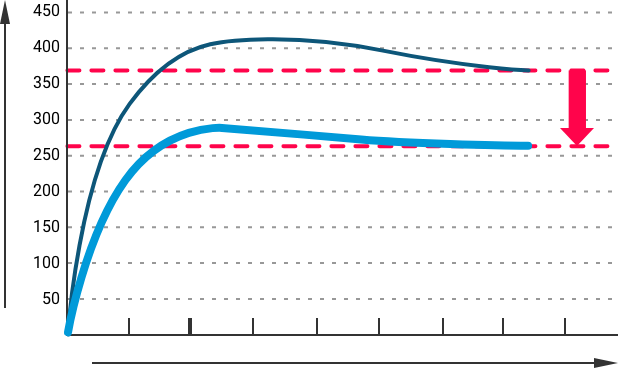

Acerca de la fuerza de frenado y la pérdida de la eficacia de frenado por sobrecalentamiento

Fuerza de frenado Tiempo Rotor ICE TECHNOLOGY Disco actual

Fuerza de frenado Tiempo Rotor ICE TECHNOLOGY Disco actualEfectos de radiación del disco de freno revestido

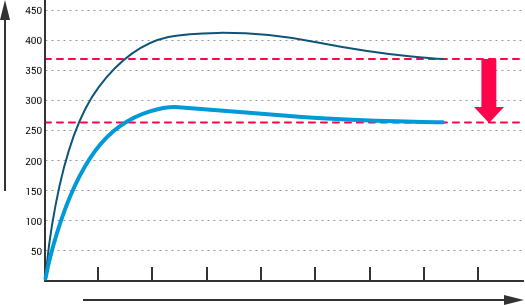

RT Temp. (°C) Tiempo Rotor ICE TECHNOLOGY Disco actual

RT Temp. (°C) Tiempo Rotor ICE TECHNOLOGY Disco actual100°C de reducción de calor

(frente a disco de freno de acero inoxidable)

* Condiciones de prueba originales de SHIMANO

ICE TECHNOLOGIES FREEZA

Los discos ICE TECHNOLOGIES FREEZA utilizan la estructura en sándwich de 3 capas de acero inoxidable-aluminio-acero inoxidable para reducir la acumulación de calor.

La capa interior de aluminio se extiende hacia el interior con una amplia aleta de radiador expuesta que potencia su capacidad de refrigeración.

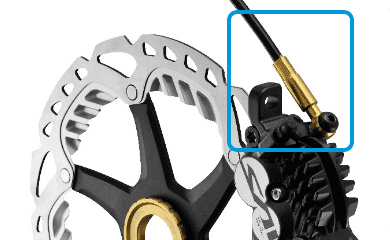

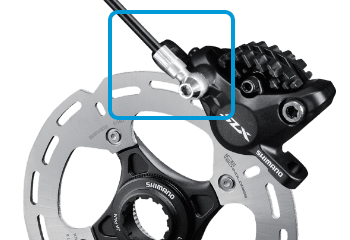

Latiguillo ICE TECHNOLOGY

El latiguillo largo tipo banjo SM-BH90-SBLS reduce el calor en un punto crítico, donde se transmite calor de la pinza al latiguillo.

Latiguillo ICE TECHNOLOGY

Latiguillo Estándar