-

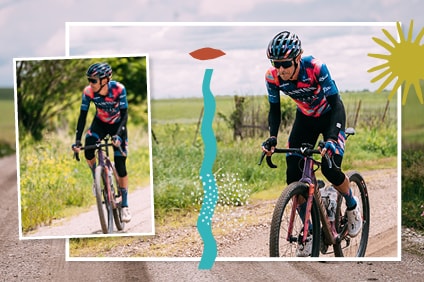

- SHIMANO Trail Born Expands Mountain Bike Trails Worldwide

- Discover how SHIMANO Trail Born is supporting trails and riding communities worldwide with 21 new projects launching in 2026.

- 18/02/2026

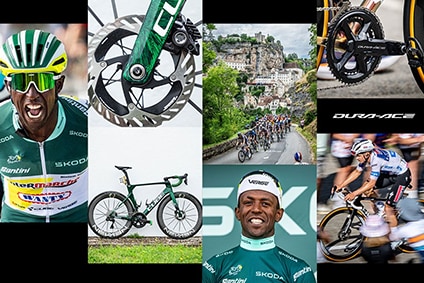

Shimano has been refining and redefining shifting performance for more than 70 years. What began with basic external shifting has evolved into some of the most precise and reliable component groupsets in cycling. Today, Shimano’s road and gravel components rely on a suite of integrated technologies designed to deliver consistent, confident shifts every time you press a lever.

Understanding how these technologies work together helps explain why Shimano drivetrains are trusted by everyone from everyday riders to WorldTour professionals.

.jpg)